- Research

-

YOU ARE

- Community member

- Future Student

- Student

- Professor

- Alumni

- Media

- Guidance counsellors

- INRS retiree

- Contact Us

- Newsroom

- Careers

- FR

-

Studies

We teach the next generation of researchers to develop scientific, social, and technological innovations.

-

Research

We find solutions through interdisciplinary research and industry or public and community partnerships.

-

INRS

We play an active role in Québec's economic, social, and cultural development.

An INRS team has developed an implant coating made with and shrimp shells, collagen, and glass to promote healing and lower the risk of rejection.

The limited bioactive properties of traditional implants can increase the length of the healing process and the risk of rejection. Photo : Adobe Stock

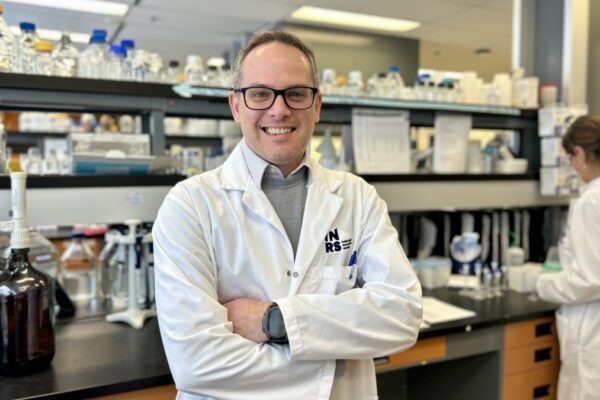

Bioactive coatings play a vital role in the success of implants such as those for knees or hips, because their properties induce a biological response that is good for the health. PhD student Imran Deen and Professor Federico Rosei from Institut national de la recherche scientifique (INRS) are working on a coating that mimics bone tissue.

“Traditional metal, ceramic, or polymer implants have limited bioactive properties. The healing process can be lengthy and have a higher risk of rejection. Developing a new generation of implant materials that promote compatibility and integration is crucial,” said Professor Rosei.

Bioactive materials

The research team is working on a cutting-edge coating based on three bioactive materials. Chitosan, found in shrimp shells, has antimicrobial properties. Collagen, the organic component of bone, facilitates cell migration and growth. And copper-doped phosphate glass stimulates blood vessel formation and bone reconstruction.

“The ability to deposit such coatings allows for the potential to make implants with tailored biological properties. It holds promise for biomedical applications, as these coatings can provide better implant-host interactions.”

Ph.D. student Imran Deen

An innovative deposition method

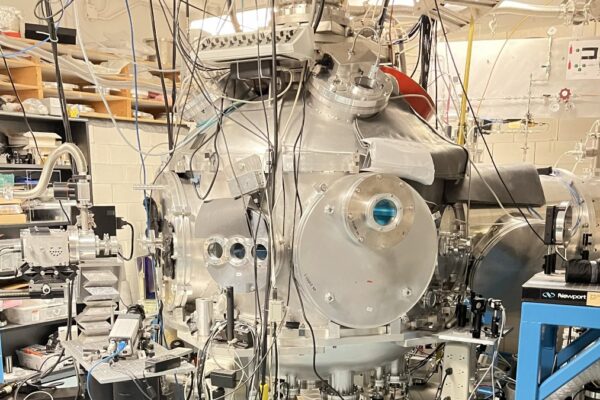

The team uses electrophoretic deposition to make the coating. The implant acts as an electrode on which bioactive material particles are deposited, forming a layer. The method does not damage the structure and properties of bioactive materials. And unlike other deposition processes currently used, it can be used at standard ambient temperature and pressure on complex shapes without expensive equipment.

The process is also versatile since the deposition can be easily adapted to specific applications. For example, the technique can be applied to hydrophilic and antimicrobial coatings, bone surface reconstruction, or coatings that are biologically and chemically inert. The product could be used to produce coronary or venous stents, in bone transplants, or in medical environments to prevent the transmission of bacteria, and thus biological infections.

The next step is to conduct additional studies to validate the proof of concept, particularly biologically. Before this type of coating is used in clinical applications, cell proliferation at the surface of the coating needs to be measured and in vivo tissue adhesion assessed.

About the study

The article called “Electrophoretic deposition of collagen/chitosan films with copper-doped phosphate glasses for orthopaedic implants ” by Imran Deen, Gurpreet Singh Selopal, Zhiming M. Wang, and Federico Rosei was published in the Journal of Colloid and Interface Science. The study received funding from the Natural Sciences and Engineering Research Council of Canada, the Canada Research Chairs, the UNESCO Chair in Materials and Technologies for Energy Conversion, Conservation and Storage (MATECSS), and the University of Electronic Science and Technology of China.

You may also like

December 22, 2021

Márta RadóShare