- Research

-

YOU ARE

- Community member

- Future Student

- Student

- Professor

- Alumni

- Media

- Guidance counsellors

- INRS retiree

- Contact Us

- Newsroom

- Careers

- FR

-

Studies

We teach the next generation of researchers to develop scientific, social, and technological innovations.

-

Research

We find solutions through interdisciplinary research and industry or public and community partnerships.

-

INRS

We play an active role in Québec's economic, social, and cultural development.

Confining a plasma jet can be stress-inducing… especially on the materials especially for shielding materials. Noting the limits inherent in the test methods currently used for these materials, Professor Patrizio Antici and his colleagues have proposed a ground-breaking new solution: using laser-accelerated particles to stress test materials subject to harsh conditions. Recently published in the journal Nature Communications, his method holds promise for a number of applications.

In a myriad of domains characterized by exposure to high energy, materials are subjected to intense stress. No matter what the high-energy application—aerospace, nuclear power plants, certain research equipment—the ability of materials to withstand the physical stress imposed on them must be assessed to avoid breakage.

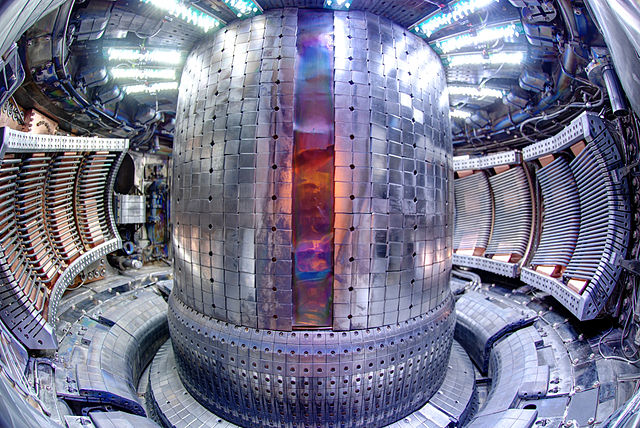

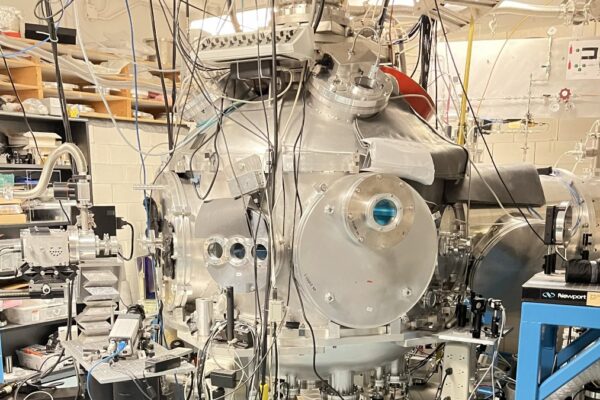

As Professor Antici himself works with state-of-the-art equipment that has to be protected at all costs from premature wear and tear, he wanted to evaluate the effectiveness of laser-accelerated particles in inducing controlled stress on materials. His method was to focus a particle beam on tungsten, graphite, titanium, tantalum, and molybdenum, all materials employed in facilities using plasma or for inertial or magnetic confinement fusion.

Currently, several methods are used to simulate wear and tear and measure the strength of these materials, but typically they provide only a partial picture, require longer protocols and are hard to model. Patrizio Antici’s high-energy experiments demonstrate that the laser-generated proton beam can reproduce damage equivalent to several months of full operation of facilities producing a harsh environment for materials. The tests are also much faster since they can be performed with more compact instruments and in a few single laser shots and allow – compared to conventional methods – to more accurately reproduce the exact operational environment to which materials are subjected.

The innovative method, which reproduces mechanical, electrical, and optical stress on five materials, can be used to improve facilities that experience conditions warranting increased protection.

For more information : “Laser-accelerated particle beams for stress testing of materials”, Nature Communications, January 25, 2018, DOI :10.1038/s41467-017-02675-x

Other articles you might be interested in

You may also like

February 14, 2018

Energy transition: A new research platform drives INRS and its partners

February 14, 2018

Modeling the deposition of metal nitride thin films by sputteringShare