- Overview

The series “Tour d’horizon en trois questions” highlights research in all its forms and takes an informed look at current events.

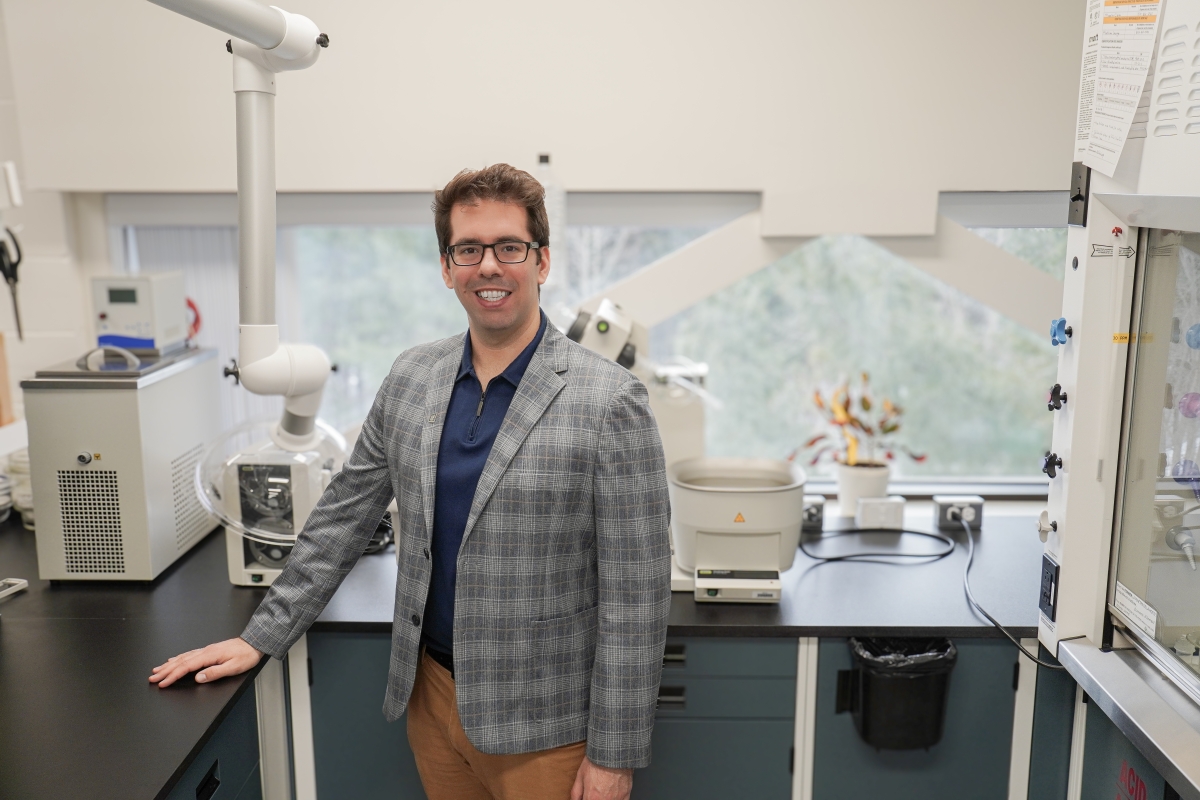

Research professor specializing in Applied electrochemistry and numerical modeling

Committed to the energy transition, Professor François Allard is focused on decarbonizing industrial processes and developing new technologies. The aim of his research is to optimize the environmental sustainability of Quebec companies in the battery and aluminum sectors.

As a specialist in applied electrochemistry and numerical modelling, François Allard is aware that research must reflect industry needs, and ensures that his work includes aspects that can be applied directly in the field. In addition to his activities as a researcher and professor at the Institut national de la recherche scientifique (INRS), François Allard acts as joint head of the INRS-UQTR Joint Research Unit in Materials and Technologies for Energy Transition.

As the consequences of climate change are increasingly evident around the world, it is essential to rethink how our materials are produced. It is in this context that Professor Allard answered our questions.

What is Quebec’s international position in the battery sector today? Is our province able to attract foreign businesses and create jobs in this sector?

Quebec is highly competitive internationally as a result of its know-how in battery materials and technology. The province is also known for its skilled workforce, its manufacturing companies in the metal and mining sector, as well as for providing favourable conditions to companies, such as green electricity and the proximity to natural resources.

In terms of research, Quebec has long been a pioneer in the development of lithium-ion batteries, with work being carried out in universities and at research centres such as those of Hydro-Québec. This work included the lithium iron phosphate (LFP) cathode, which is used as a positive electrode in the cells that make up batteries. To provide an idea of the importance of this material, the cathode accounts for about 50% of the cost of a battery, according to data from BloombergNEF. These cathodes can be found not only in electric vehicles, but also in other energy storage systems.

Today, the city of Bécancour, located in the Centre-du-Québec region, is home to major industry players, ranging from the processing of minerals from mines to the manufacture of cathode and anode active materials. Foreign companies such as Ultium CAM (a joint venture of General Motors and POSCO) and EcoPro BM are setting up facilities in Bécancour to manufacture cathode materials for electric vehicles. There are companies based in or from Quebec, such as Nouveau Monde Graphite and Nemaska Lithium, which will produce anodes, the negative electrode of the lithium-ion battery, and lithium used in the manufacture of batteries.

Cathode producers will need nickel, iron, manganese, cobalt and possibly decarbonized aluminum to provide a green product. Quebec has all these minerals, with the exception of cobalt, which we would like to eliminate from batteries through our ongoing research. INRS and Université du Québec à Trois-Rivières (UQTR) have created a partnership called the Joint Research Unit (UMR), where faculty members and student-researcher members develop the materials and technologies required for the energy transition.

In addition, these local and international companies create hundreds of new jobs, resulting in a significant need for training. Our goal is to train their teams well to support their ambition for excellence. To respond to this need, I head a platform on transportation electrification and component development involving INRS and UQTR as well as three CEGEPs (Trois-Rivières, Shawinigan and Saint-Jérôme) and two college technology transfer centres (CNETE and IVI).

INRS recently set up new laboratories to meet the innovation needs of the battery sector in terms of energy performance. Could you tell us more about these major infrastructures and their purpose?

This new sector requires that we adapt to fully meet its needs in terms of R&D and training. This is why INRS recently set up new laboratories within the INRS-UQTR UMR on energy transition to develop materials for batteries, design emerging technologies and decarbonize industrial processes.

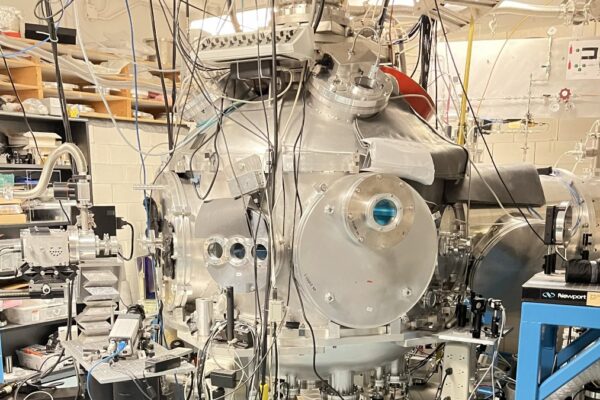

Our infrastructure not only enables UMR’s research projects on energy transition to move forward, but also trains battery specialists in a region where there is demand. For example, we are implementing a new materials synthesis and characterization platform for solid-state batteries, meaning, that do not use any flammable electrolytes. We also have spaces for the study of aluminium production processes by electrolysis, as well as the recycling of used lithium-ion batteries and cyclers (devices for charging and discharging batteries). We use this research equipment namely to assess the performance of new technologies developed with our partners and collaborators in Quebec and internationally.

Our new laboratories make it possible to perform small-scale assessments of the behaviour of new materials in batteries. We test materials that help improve the range of electric vehicles while using resources available in Quebec. In addition, we are looking at how to optimize the recycling process for lithium batteries to support the new facilities in this area.

Your work also focuses on the decarbonization of aluminum production in Quebec. How does the energy transition translate to this industry? In what way are these changes essential for Quebec?

Competition in the primary production of aluminum is fierce, with Canada being ranked fourth in the world. In Quebec, nearly three million tonnes are produced each year. Our aluminum is the greenest in the world since it is produced from hydroelectricity.

The current process must still be continuously optimized to ensure our competitiveness, both environmentally and economically. To achieve this, I implemented various projects at INRS to develop corrosion-resistant materials that will ultimately enable the instrumentation of primary aluminum production units (electrolysis cell) and better optimize them (energy efficiency). In addition, some of these materials will enable the life of production units to be extended.

It is important to know that the production of aluminum takes place in a very corrosive environment and that electrolysis cells operate at close to 1000°C. The research challenges are therefore significant, but we have created an experienced team to develop these new materials. I work with Professors Lionel Roué and Daniel Guay from the INRS Énergie Matériaux Télécommunications Research Centre, as well as with Université de Sherbrooke, which produces numerical models to fully integrate these materials into the partner’s production units.

Ultimately, these research projects will help aluminium production plants in Canada and around the world improve their economic and environmental performance while reducing waste generation and greenhouse gas emissions.

In the field of transportation, aluminium plays a major role in reducing the weight of electric and hybrid vehicles, which can increase their range or reduce the number of batteries that are needed. Aluminium is also used in the manufacture of lithium nickel-cobalt-aluminum oxide (NCA) cathodes, which are used by some car manufacturers. Our research is therefore essential for decarbonizing our economy and the transport sector in the future.