How to eliminate emerging refractory contaminants such as drug residues in hospital wastewater. How to disinfect and treat water without chemicals. How to treat wastewater using renewable energy. Laboratory of Environmental Electrotechnologies and Oxidative Processes (LEEPO) finds solutions to all these issues.

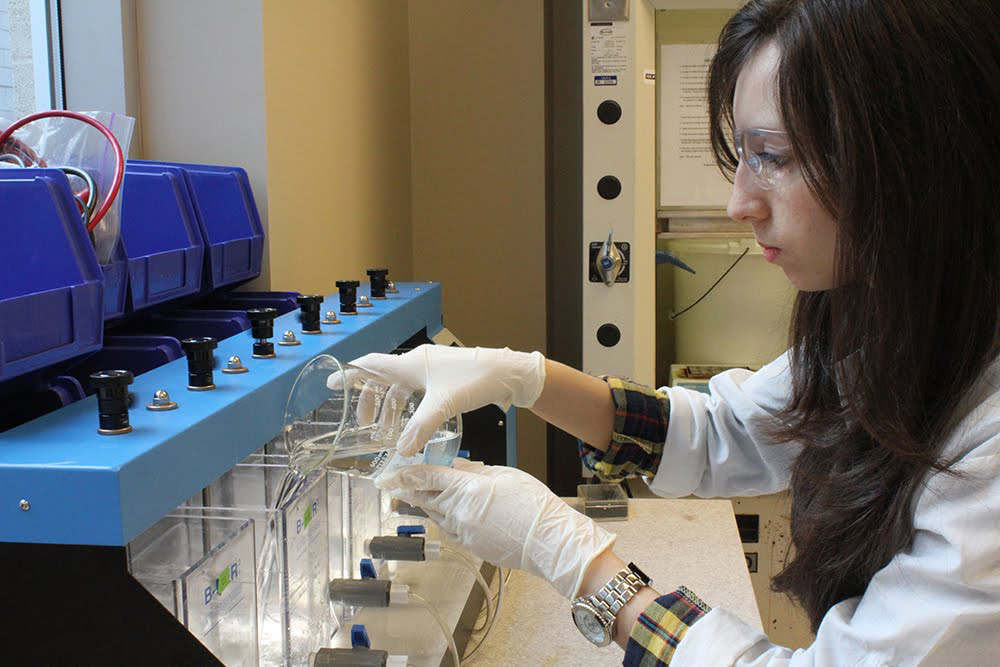

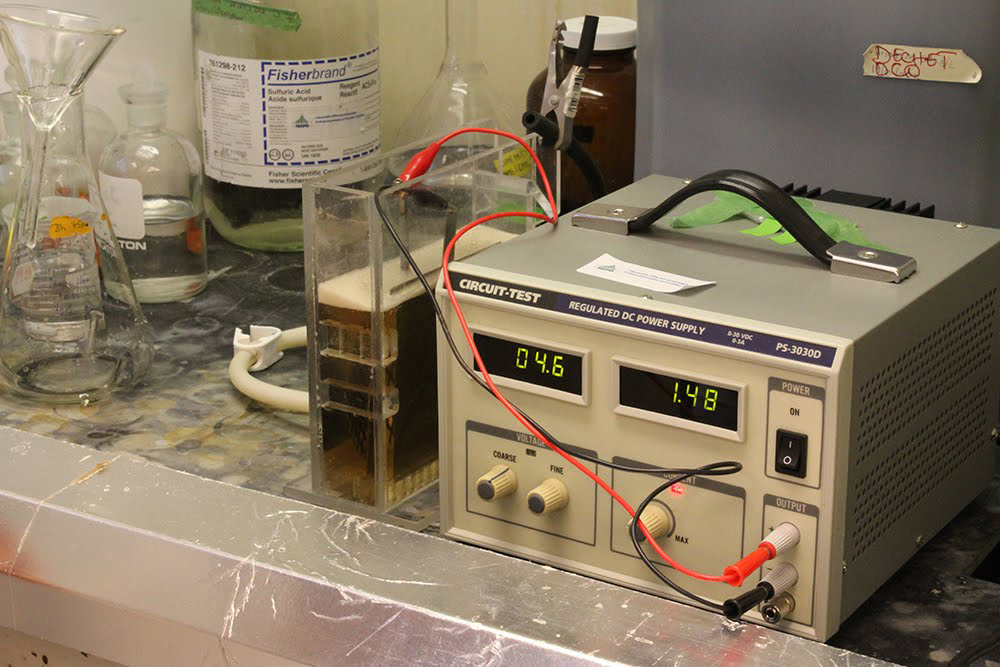

LEEPO develops electrolytic techniques and oxidative processes to improve water treatment systems (from drinking water to municipal and industrial wastewater treatment) and replace inefficient conventional technologies for removing refractory organic, inorganic, and microbial contaminants.

- Electro-oxidation/electrodeposition (EC-ED) treatment units, 2 m high and 1 m wide each (2)

- Electrocoagulation/electroflotation (EC-EF) treatment units, 2 m high and 1 m wide each (2)

- Tangential ultrafiltration/microfiltration treatment unit, 2 m high and 1 m wide

- Membrane bioreactor (MBR) treatment unit, 2 m high and 1 m wide (three laboratory membrane bioreactors, including electro-MBR)

- Photo-catalytic unit

- Two electro-photocatalytic units

- Ozonation treatment unit

- Sonication treatment unit

- UV cell

- Jar-test shaker unit

- Thermoregulator

- HDPE reactor (10, 15, and 30 gallons)

- Two solar simulators

- Small equipment: shakers, pH-meters, etc.

- Cary 50 UC/visible light spectrophotometer with microplate reader coupled to a computer

- Potentiostatic/galvanostatic Voltlab 80 analytical radiometer coupled to a computer

- Potentiometric titrator coupled to a computer

- Turbidity metre

- Hot plates and shakers

- Rotary evaporator

- Lubricated pumps for vacuum filtration (2)

- Oxygen analyzer

- Hach COD/TOC reactor

- Oven

- Analytical scales

- Chemicals

- Storage space for various types of electrodes

- Crucibles, pans, mortars, etc.

- EC-EF pilot-scale unit (200 to 300 L)

- EO-ED pilot-scale unit (200 to 300 L)

- Electromembrane (EM) pilot-scale unit (200 to 300 L)

- Green/advanced decontamination and decentralized wastewater treatment technologies (NSERC Discovery Grant)

- Development of a hybrid process for decontaminating and reusing wastewater from commercial laundries (NSERC Collaborative Research and Development Grant)

- Development of electrolytic processes for recovering and reusing chloride salts from road de-icing water for disinfecting drinking water (NSERC Collaborative Research and Development Grant)

- Development of an innovative membrane bio-treatment technology for leachates from static composting piles (NSERC Collaborative Research and Development Grant)

- Prototype design and technology transfer of a portable electrolytic water treatment unit for use in rural areas (grant from Ministère des Relations internationales et de la Francophonie, Quebec-Haïti cooperation program).

- Development of an innovative catalytic absorption process using xerogels to eliminate emerging pollutants (grant from Ministère des Relations internationales et de la Francophonie, Quebec-Wallonia-Brussels cooperation program)

- Development of a hybrid system for the treatment of agri-food effluents contaminated by antibiotics and hormones (grant from Ministère des Relations internationales et de la Francophonie, Quebec-Mexico Working Group)

- Source removal of drug residues from hospital wastewater: an innovative approach to treating emerging contaminants (NSERC Strategic Project Grant)

- Feasibility of producing bioplastics from cashew apple juice in Ivory Coast (grant from INP-HB, Ivory Coast)

- Development of ultra-oxidizing electrolytic technology for tertiary treatment of slaughterhouse wastewater (contract with PLT Environnement Inc.)

- Treatment of landfill leachate by combining biofiltration through an organic medium (BIOSOR) and electrocoagulation (FRQNT Innovation Networks Support Program grant)

- Development of electrotechnologies to treat water contaminated by endocrine disruptors and other inorganic and microbial pollutants (NSERC Discovery Grant)

- Study on the performance of an activated carbon treatment unit for the removal of cyanobacteria and cyanotoxins from drinking water (Service contract with Roches Ltd., Consulting Group)

Contacts

Boutaina El Jai

Partnerships and Research Development Advisor

Phone: 418 654-2531

boutaina.el_jai@inrs.ca

Laboratory of Environmental Electrotechnologies and Oxidative Processes

Institut national de la recherche scientifique

Eau Terre Environnement Research Centre

490 rue de la Couronne

Quebec City, Quebec G1K 9A9

Canada